-

Late Jacks flurry propels England to 184-7 against Nepal

Late Jacks flurry propels England to 184-7 against Nepal

-

Vonn crashes out of Winter Olympics, ending medal dream

-

All-new Ioniq 3 coming in 2026

All-new Ioniq 3 coming in 2026

-

New Twingo e-tech is at the starting line

-

New Ypsilon and Ypsilon hf

New Ypsilon and Ypsilon hf

-

The Cupra Raval will be launched in 2026

-

New id.Polo comes electric

New id.Polo comes electric

-

Iran defies US threats to insist on right to enrich uranium

-

Seifert powers New Zealand to their record T20 World Cup chase

Seifert powers New Zealand to their record T20 World Cup chase

-

Naib's fifty lifts Afghanistan to 182-6 against New Zealand

-

Paul Thomas Anderson wins top director prize for 'One Battle After Another'

Paul Thomas Anderson wins top director prize for 'One Battle After Another'

-

De Beers sale drags in diamond doldrums

-

NFL embraces fashion as league seeks new audiences

NFL embraces fashion as league seeks new audiences

-

What's at stake for Indian agriculture in Trump's trade deal?

-

Real Madrid can wait - Siraj's dream night after late T20 call-up

Real Madrid can wait - Siraj's dream night after late T20 call-up

-

Castle's monster night fuels Spurs, Rockets rally to beat Thunder

-

Japan votes in snow-hit snap polls as Takaichi eyes strong mandate

Japan votes in snow-hit snap polls as Takaichi eyes strong mandate

-

Pakistan's capital picks concrete over trees, angering residents

-

Berlin's crumbling 'Russian houses' trapped in bureaucratic limbo

Berlin's crumbling 'Russian houses' trapped in bureaucratic limbo

-

Neglected killer: kala-azar disease surges in Kenya

-

Super Bowl set for Patriots-Seahawks showdown as politics swirl

Super Bowl set for Patriots-Seahawks showdown as politics swirl

-

Sengun shines as Rockets rally to beat NBA champion Thunder

-

Matsuyama grabs PGA Phoenix Open lead with Hisatsune one back

Matsuyama grabs PGA Phoenix Open lead with Hisatsune one back

-

Washington Post CEO out after sweeping job cuts

-

Haiti's transitional council hands power to PM

Haiti's transitional council hands power to PM

-

N. Korea to hold party congress in February, first since 2021

-

Thailand votes after three leaders in two years

Thailand votes after three leaders in two years

-

Swiss joy as Von Allmen wins first gold of Winter Olympics

-

George backs England to 'kick on' after Six Nations rout of Wales

George backs England to 'kick on' after Six Nations rout of Wales

-

Malinin upstaged as Japan keep pressure on USA in skating team event

-

Vail's golden comets Vonn and Shiffrin inspire those who follow

Vail's golden comets Vonn and Shiffrin inspire those who follow

-

Veteran French politician loses culture post over Epstein links

-

Japan's Kimura wins Olympic snowboard big air gold

Japan's Kimura wins Olympic snowboard big air gold

-

Arteta backs confident Gyokeres to hit 'highest level'

-

Hojlund the hero as Napoli snatch late win at Genoa

Hojlund the hero as Napoli snatch late win at Genoa

-

England's Arundell 'frustrated' despite hat-trick in Wales romp

-

Lollobrigida skates to first Italian gold of Winter Olympics on her birthday

Lollobrigida skates to first Italian gold of Winter Olympics on her birthday

-

Arundell hat-trick inspires England thrashing of Wales in Six Nations opener

-

Chile's climate summit chief to lead plastic pollution treaty talks

Chile's climate summit chief to lead plastic pollution treaty talks

-

Rosenior hails 'unstoppable' Palmer after treble tames Wolves

-

French ex-minister offers resignation from Paris cultural hub over Epstein links

French ex-minister offers resignation from Paris cultural hub over Epstein links

-

New NBA dunk contest champ assured and shooting stars return

-

Shiffrin says will use lessons learnt from Beijing flop at 2026 Games

Shiffrin says will use lessons learnt from Beijing flop at 2026 Games

-

Takaichi tipped for big win as Japan votes

-

Lens return top of Ligue 1 with win over Rennes

Lens return top of Ligue 1 with win over Rennes

-

Shiffrin learning from Beijing lessons ahead of Milan-Cortina bow

-

Demonstrators in Berlin call for fall of Iran's Islamic republic

Demonstrators in Berlin call for fall of Iran's Islamic republic

-

'Free the mountains!": clashes at Milan protest over Winter Olympics

-

Townsend accepts pressure will mount on him after Italy defeat

Townsend accepts pressure will mount on him after Italy defeat

-

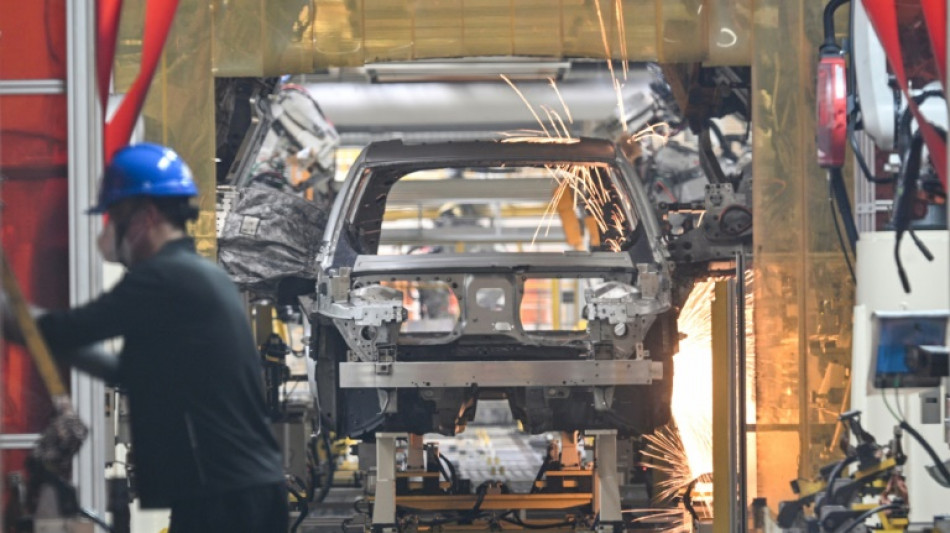

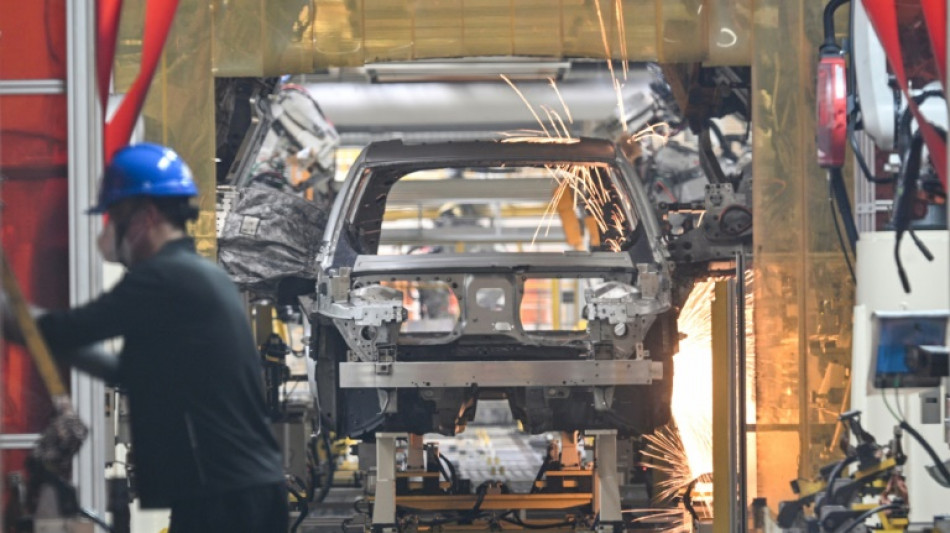

BMW iX3 new style and design

Foreign carmakers strive for 'China Speed' to stay in race

In fluid synchronisation, dozens of robotic arms picked up metal parts and welded them onto vehicle beds, as car skeletons gradually took shape and progressed along an automated factory floor near the eastern Chinese city of Ningbo.

Across the country, car models rolling off assembly lines like this have gone from concept to release in record time -- known in the industry as "China Speed", the envy of foreign competitors.

At EV firm Zeekr's vast Ningbo plant, advanced robotics and artificial intelligence have been leveraged at every stage of the manufacturing process to save huge amounts of time and money.

In the casting shop, a robotic arm that towered over the human foremen supervising it picked up a freshly made piece of aluminium and dunked it into a vat of water, sending steam hissing out, before passing the metal to another machine to cut and press it.

The factory still employs around 2,500 workers to do some delicate tasks and for quality control.

But the heavy lifting is done by hundreds of tireless robots, with some processes going on 24 hours a day.

And it's not just manufacturing that has been accelerated.

Zeekr has a research and development base in Sweden, which allows workloads to be shared across timezones. Its parent company, Geely, also owns Swedish automaker Volvo.

In the factory's car park, hundreds of gleaming, plate-less Zeekr 7X SUVs stood ready to be transported to dealerships.

"The future is our history," read a slogan above the entrance hall.

- 'Make-or-break moment' -

Factories and companies like this have set a new pace in the industry.

"We are at a make-or-break moment for established global automakers," a recent report by consulting firm Bain & Company said.

En route to the factory, AFP saw lorries carrying brand new Zeekr cars headed to Ningbo's huge port, bound for export to places like Australia.

The most innovative Chinese manufacturers spend less than a third of that spent by traditional competitors to develop new vehicles, the Bain report said.

While legacy automakers often take 48 to 54 months to bring out new models, the timeline for younger brands is more like 24 to 30, it added.

Some of Zeekr's models only took 15 months to develop, a spokesman told AFP.

The results are clear in the sheer choice available to consumers: There are currently 2,755 models on offer from 163 brands in the Chinese market, authorities say.

At industry show Auto Shanghai, which opened Wednesday, more than 100 new models were launched.

Jostling in the pack were not just Chinese firms like Zeekr, BYD and Chery, but also foreign rivals hitting the gas to catch up.

Volkswagen and Nissan launched tens of new models developed "in China for China" at the show, with executives insisting they had adapted to "China Speed".

The acceleration has been helped by the shift towards EVs, disposing of the complex internal combustion engine.

"You start by designing the car virtually, making as few prototypes as possible, so you can move very quickly," BCG consultant Mikael Le Mouellic told AFP.

Design and engineering will then work hand-in-hand, and often "reuse recipes that work", he added.

Zeekr's "Sustainable Experience Architecture", for example, can be the bed for A-class to E-class cars, saving time and money.

- Three years to nine months -

Foreign suppliers have also had to adapt.

Traditionally, companies could take up to three years to design, for example, a new headlamp, said Michael Fischer, boss at French automotive parts maker Forvia.

"In China that doesn't work," he said.

Now, "we have a process that is going to be very organised, that's going to secure for quality, but can bring up a new headlamp in as little as nine months".

At competitor Valeo's factory in Changshu, north of Shanghai, four large robots assembled LED headlamps for Zeekr and other brands.

"We don't work 24/7!" joked Valeo's innovation manager in China, Gu Jianmin. "But we use existing solutions, and we work upstream with the automakers."

Development and durability tests that "would have taken months" are helped along by AI and other technology.

"Chinese manufacturers are a little more demanding. But foreigners are trying to catch up," said Gu.

"To emerge in China, you have to be at the same level as the locals."

X.Brito--PC